-

Machine tools

-

Machine tool accessories

-

Welding, cutting equipment

-

OEM Machined parts, components

| Parameter | Data |

| Outer diameter | 2000 mm |

| Clamping diameters range | 100-2100 mm |

| Back mount | DIN 55026 A2-20 (ISO 702/I), optional as DIN 55022, 55027, 55029 or other types |

| Maximum speed | 150 RPM |

| Net weight | 2720 KG |

| Screw rods, master jaws | 40Cr alloy steel made, quenched & hardened to hardness HRC 38-42 |

| Top jaws | 42CrMo alloy steel made, through-quenched to hardness HRC 50-55 |

2000mm Heavy-duty 4-jaw indpendent chuck with A2-15 back or other types of back mount to fit on lathe's spindle nose. This chuck base is made of casting steel for high rigidity. With the assistant supporting from the roller-type open steady rests, this 2m heavy-duty chuck can carry workpiece with maximum weight of 200 Metri Tons. Therefore, it is widely used on heavy-duty horizontal lathes in nuclear equipment plants, steel roll plants, turbine production plants and other heavy-industrial plants, for proceeding turning, deep-hole boring, etc.;

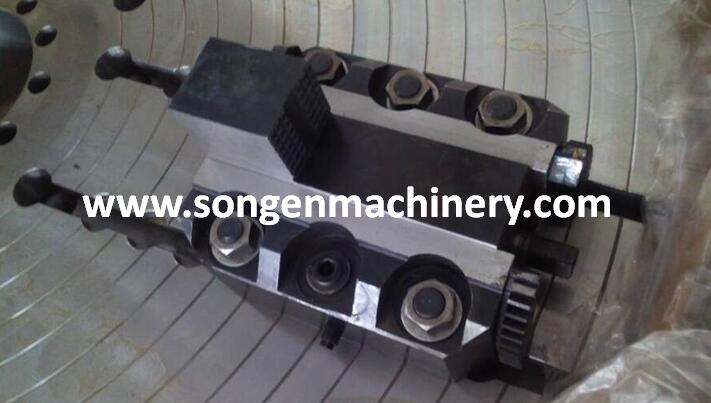

4 Pcs of bolt-on box jaws are fitted on top of it for works clamping and holdings. On each piece of boring mill jaws, gear sections are fitted for boosting the clamping forces of each jaws to tens of Tons to hold huge workpieces. On requests, 6-jaw, 8-jaw, 10-jaw can be furnished to this chuck to add its clamping versatility. These boring mill jaws can be used also independently on any face plates made by yourself to match the lathe;

On this 2000mm 4-jaw independent chuck, all its designing features are entirely custom made to meet our customer's specific requirements. If you have a horizontal lathe calling for a customzied chuck of this style,or you need boring mill jaws to be fitted with your selfmade faceplates, please contact us at sam@songenmachinery.com, we will definitely provide you valuable offer to improve your ideas on sourcing for a proper heavy-duty 4-jaw independent chuck.

Horizontal lathes

Horizontal lathes