-

Machine tools

-

Machine tool accessories

-

Welding, cutting equipment

-

OEM Machined parts, components

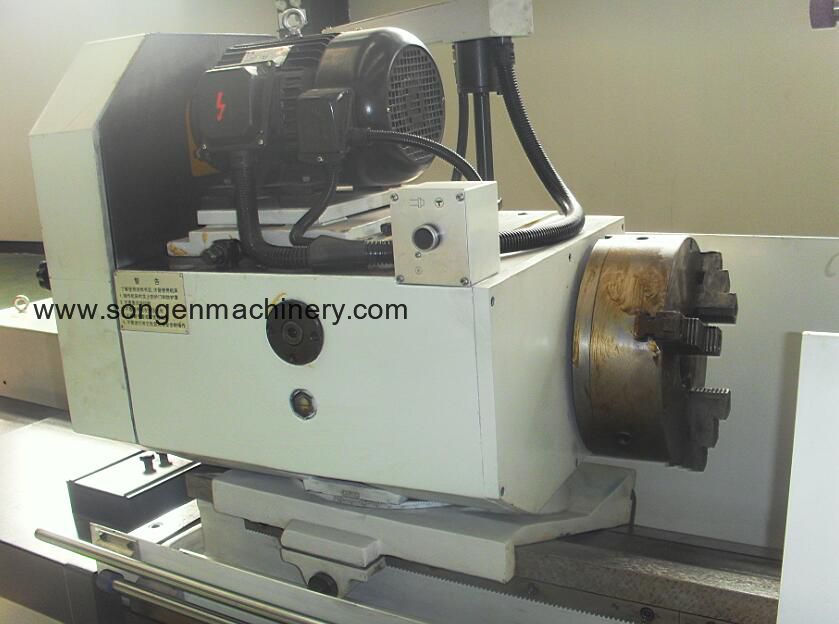

1. The UCG500/200 universal cylindricall grinder is widely used to grind external (or internal) cylindrical (or conical) surfaces of rotational parts in single-piece, small-batch and mass productions. It is a generally purposed cylindrical grinder and can be operated in grinding parts and componentes for various industries;

2. This universal cylindrical grinder can hold workpieces with weight up to 1000 KG. The distances between two centers (one is on the workhead, the other is on the tailstock) are available as standard 1500, 2000, 3000, 4000 mm. We can also custom make the cylindrical grinder to have a D.B.C. of more then 4000mm on request;

3. Machine base consists of the base supporting the grinding wheel head and the base supporting the worktable, the work head and the tailstock etc.. All the machine bases are made of high-density and high-strength gray cast iron which has been carefully heat-treated with twice annealment to eliminate the residual internal stress to the minimum, therefore the machine bases avoid distortion and enable the cylindrical grinder to retain its high performance accuracy in the long-term operations;

Working Accuracy:

| Roundness(outer circle/inner circle) |

3μm for D.B.C. 1500mm grinder 5μm for D.B.C. 2000/3000/4000mm grinders |

| Dia. Uniformity in the long. section |

8μm for D.B.C. 1500mm grinder 10μm for D.B.C. 2000/3000mm grinders 15μm for D.B.C. 4000mm grinder |

| Surface roughness(outer circle/inner circle) | Ra0.16μm/ Ra0.63μm |

Standard accessories:

1. 3-Jaw self-centering chuck, OD 325mm;

2. Open-type steady rest;

3. Carbide tipped center, MT #6;

4. Internal grinding attachment, 10000 RPM speed;

5. External grinding wheel, OD500 x Width75 x ID305;

6. Internal grinding wheel, OD30 x Width25 x ID10;

7. Grinding wheel pressing plate;

8. Grinding wheel periphery dresser;

9. Grinding wheel balancing mandrel;

10. Grinding wheel detaching wrench;

11. Measuring bridge plate;

12. Machine leveling & anchor mounts;

13. Driving rod and lathe dog;

14. Coolant system;

15. Hydraulic power unit.

Optional accessories:

1. 4-Jaw independent chuck, OD 320 mm;

2. Grinding wheel balancing stand;

3. Grinding wheel circular dresser;

4. Grinding wheel end face dresser;

5. Carbide heavy-duty center;

6. Close-type steady rest;

7. Half-notched center;

8. Magnetic separator;

9. Center grinding attachment.

| Specifications | Unit | UCG500/200 x 1500/2000/3000/4000 | |||||||

| GENERAL CAPACITY | |||||||||

| Maximum distance between centers | mm | 1500/2000/3000/4000 mm | |||||||

| Center height | mm | 270 | |||||||

| Diameter ground (OD) | mm | 25 - 500 | |||||||

| Diameter ground (ID) | mm | 30 - 200 | |||||||

| Maximum length ground (OD) | mm | 1500/2000/3000/4000 mm | |||||||

| Maximum length ground (ID) | mm | 450 | |||||||

| Maximum weight of workpiece | KG | 1000 | |||||||

| WORK HEAD | |||||||||

| Swivel angle | Degrees | Counter clockwise 90 | |||||||

| Center taper | MT | #6 | |||||||

| Spindle speed | RPM | 50Hz: 20 - 224, Stepless | |||||||

| GRINDING WHEEL HEAD | |||||||||

| Wheel spindle speed | RPM | High: 1330; Low: 665 | |||||||

| Wheel rapid traverse travel | mm | 100 | |||||||

| Maximum travel of wheel | mm | 370 | |||||||

| Swivel angle | Degrees | Clockwise: 30; Counter-clockwise: 0 | |||||||

| Feed per hand wheel revolution | mm | Rough: 4.0; Fine: 0.5 | |||||||

| Feed per graduation on hand wheel scale | mm | Rough: 0.02; Fine: 0.0025 | |||||||

| Minimum periodically feed | mm | Rough: 0.02; Fine: 0.0025 | |||||||

| Diameters of grinding wheels | mm | Maximum: 500 mm; Minimum: 400 mm | |||||||

| INTERNAL GRINDING ATTACHMENT | |||||||||

| Spindle speed | RPM | 6000 | |||||||

| Size of grinding wheel (OD x Width x ID) | mm | Max. 50 x 25 x 20; Min. 17 x 20 x 6 | |||||||

| WORKTABLE | |||||||||

| Feed per hand wheel revolution | mm | 6 | |||||||

| Maximum swivel angle | Degrees | Clockwise | 3 | 2 | 2 | 1 | |||

| Counterclockwise | 6 | 5 | 3 | 2 | |||||

| mm | for D.B.C. | 1500 | 2000 | 3000 | 4000 | ||||

| Longitudinal rapid traverse speed | mm/Minute | 10 - 3000 | |||||||

| TAILSTOCK | |||||||||

| Center taper | MT | #6 | |||||||

| Quill travel | mm | 70 | |||||||

| MOTORS | |||||||||

| Grinding wheel head motor | KW | 5.5 / 7.5, Double-Speed Motor | |||||||

| Internal grinding attachment motor | KW | 1.5 | |||||||

| Work head motor | KW | 4, AC Variable Frequency Motor | |||||||

| MACHINE SIZES AND WEIGHTS | |||||||||

| Gross weight /Packing size | KG / cm |

12000 / 510x228x210, for D.B.C. 1500 mm 13000 / 585x228x210, for D.B.C. 2000 mm 15000 / 785x228x210, for D.B.C. 3000 mm 17000 / 1000x228x210, for D.B.C. 4000 mm |

|||||||

Horizontal lathes

Horizontal lathes