-

Machine tools

-

Machine tool accessories

-

Welding, cutting equipment

-

OEM Machined parts, components

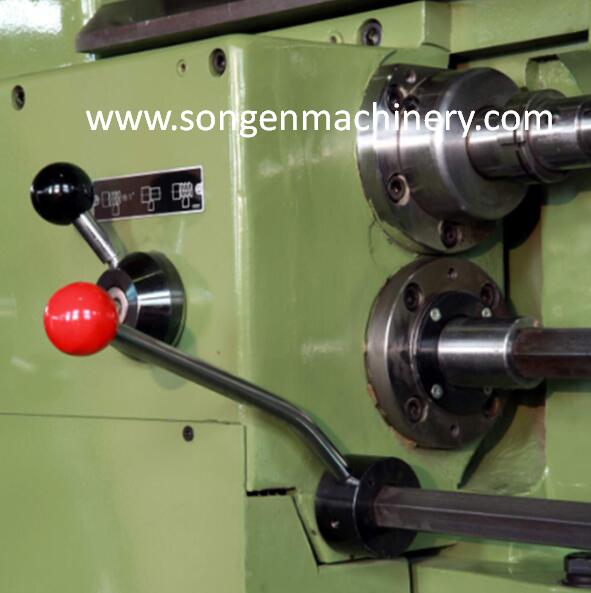

Gear-headed with high spindle speeds (maximum as 2000 RPM) for precision turning;

Very rigid machine bed in the double-wall structure with heavy ribbing;

Guide ways ultrasonic frequency quenched and precision ground to ensure a long accurate service life;

Removable gap for large swing;

Gears in headstock and feed gearbox hardened and precision ground for low noise in running;

Spindle mounted on high-precision tapered roller bearings and high-precision angular contact ball bearings for high-speed and accurate revolutions;

Maximum accuracy and quiet operation even at high speed;

High machining performance with 5.5 KW main drive;

Spindle bore diameter 52mm for machining of long bars;

Feed gearbox well sealed to eliminate leakage;

Kinds of metric threads, inch threads, diametrical pitch threads and module threads;

Tailstock locked by thread and cam lock;

Electric system is reliable and safe;

CE-conformity electromagnetic brake at users option;

Digital readout 2-Axis or 3-Axis can be mounted as an option;

Machine color at buyer option.

Standard accessories:

l 3-Jaw self-centering chuck c/w one set of reversible top jaws;

l 4-Jaw chuck with reversible top jaws;

l Face plate;

l Chasing dial indicator;

l Lead screw guard.

l Steady rest;

l Follow rest;

l Dead centers;

l Splash guard;

l Halogen work lamp;

l Stand & oil tray;

l Toolbox & tools;

l Coolant system;

l Foot clutch.

Optional accessories:

l Taper turning attachment;

l Lead screw guard;

l Quick change tool post;

l Digital readout (2-Axis or 3-Axis);

l Driving plate;

l Live center;

l Chuck guard;

l Drill chuck and drill arbor.

SPECIFICATION | MODEL |

SN50Bx1000/1500/2000 | |

CAPACITY | |

Swing over red | 500 mm |

Swing over cross slide | 270 mm |

Swing in gap | 700 mm |

Length of gap | 230 mm |

Distance between centers | 1000, 1500, 2000 mm |

Center height over bed | 250 mm |

340 mm | |

Max. workpiece weight supported between centers | 300 KG |

Max. workpiece weight supported with chuck only | 80 KG |

HEADSTOCK | |

Spindle nose | STN ISO 702/II - C6 |

Spindle bore | 80mm |

Taper of spindle bore | No.6 Morse |

Spindle peed | 24 Steps, 22.4-2000 RPM |

FEEDS AND THREADS | |

Max.travel of compound rest | 140 mm |

Max.travel of cross slide | 300 mm |

Max. section of tool | 32×20mm |

Longitudinal feeds range | 38 Kinds, 0.05-6.4 mm/Rev. |

Cross feeds range | 38 Kinds, 0.025-3.3 mm/Rev. |

Rapid traverse, Longitudinal | 3000 mm/Minute |

Rapid traverse, Cross | 1500 mm/Minute |

Metric threads range | 29 Kinds, 0.5-40 mm |

Inch threads range | 38 Kinds, 1-80 T.P.I. |

Diametrical pitches range | 31 Kinds, 2-72 D.P. |

Module pitches range | 26 Kinds, 0.25-20 mm |

TALLSTOCK | |

Quill bore diameter | 70 mm |

Travel of tailstock sleeve | 180 mm |

Morse taper of tailstock sleeve | No.5 Morse |

Cross resetting | ±12 mm |

MOTOR | |

Power of main motor | 5.5 KW |

Power of coolant pump | 0.1 KW |

DIMENSION AND WEIGHT | |

Overall

dimension (L x W x H) |

|

Net

weight |

|

Horizontal lathes

Horizontal lathes